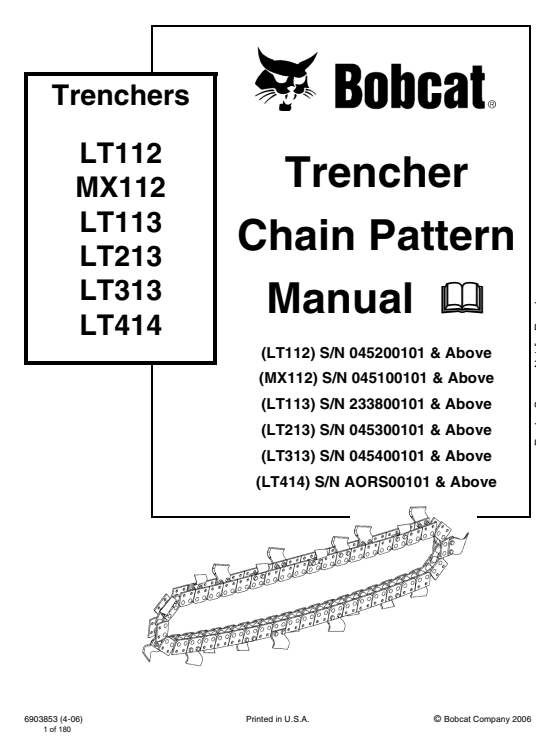

Bobcat Trencher Chain Pattern Manual

$5.00

Compatible Machine Model :Bobcat Trencher Chain Pattern

Compatible Serial Numbers :

(LT112) S/N 045200101 & Above

(MX112) S/N 045100101 & Above

(LT113) S/N 233800101 & Above

(LT213) S/N 045300101 & Above

(LT313) S/N 045400101 & Above

(LT414) S/N A0RS00101 & Above

BEFORE YOU BUY FULL PDF MANUAL, PLEASE DOWNLOAD SAMPLE OF THIS PDF MANUAL AND PLEASE CHECK IT IS COMPATIBLE WITH YOUR MODEL

Description

Package Include

Bobcat Trencher Chain Pattern Manual

Language

English

Format

PDF

Total Number of pages

1-136

Publication Number

6903281

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 20 mb

Compatible Machine Model :Bobcat Trencher Chain Pattern

Compatible Serial Numbers :

(LT112) S/N 045200101 & Above

(MX112) S/N 045100101 & Above

(LT113) S/N 233800101 & Above

(LT213) S/N 045300101 & Above

(LT313) S/N 045400101 & Above

(LT414) S/N A0RS00101 & Above

Introduction to Bobcat Trenchers

Bobcat trenchers are specialized excavation machines designed to dig narrow trenches for various applications, including utility installation, irrigation systems, and landscaping projects. These machines are equipped with powerful engines and robust digging chains that enable efficient trenching in diverse soil conditions. The primary function of a Bobcat trencher is to create precise and clean trenches, which are essential for laying pipes, cables, and other underground infrastructures.

One of the standout features of Bobcat trenchers is their design, which combines maneuverability and power. The compact size allows operators to navigate tight spaces often found in residential settings while still providing high digging performance. Additionally, Bobcat trenchers are available in various models with different digging widths and depths, catering to the specific needs of both contractors and DIY enthusiasts.

The importance of understanding trenching chain patterns cannot be understated when it comes to optimizing performance. The trencher’s chain is responsible for the quality of the excavation, influencing how effectively the machine can cut through various types of soil and debris. Correctly matching the chain pattern to the project’s requirements greatly enhances efficiency and minimizes wear on the equipment.

In commercial applications, Bobcat trenchers prove invaluable in completing large-scale projects swiftly. These machines are commonly used by landscapers, plumbers, and utility companies due to their reliability and exceptional performance. In residential settings, they are favored for their ability to perform trenching tasks without disturbing the surrounding landscape excessively. The advantages of utilizing Bobcat equipment extend beyond mere functionality; their ease of use and maintenance ensures that operators can focus on executing tasks efficiently while achieving optimal results.

Detailed Guide to Trencher Chain Patterns

Bobcat trenchers are renowned for their efficiency and precision, and a vital component that influences this efficiency is the trencher chain pattern. Understanding the various types of trencher chain patterns is essential for operators, as these patterns directly impact the performance of the machine in differing soil conditions. The range of chain patterns includes standard, heavy-duty, and specialized configurations, each designed for specific tasks and environments. For instance, standard patterns are generally suitable for softer soils, while heavy-duty patterns excel in rocky or abrasive terrains.

The configuration of the trencher chain plays a crucial role in the digging process. The pitch, link spacing, and the arrangement of the teeth can significantly affect how well the trencher can penetrate the ground. Chains with closely spaced teeth are more effective at breaking up compact soil, whereas those with wider spacing can efficiently move through softer, loose materials. When selecting the appropriate chain configuration, operators must consider factors such as trenching depth and the specific machine’s compatibility.

Soil conditions are an additional determinant when choosing the right trencher chain pattern. For instance, in clay-heavy soils, a chain with specialized teeth designed to cut through dense material will yield better results than a standard pattern. Conversely, for rocky terrains, heavy-duty chains equipped with reinforced components will enhance durability and performance. Regular maintenance of trencher chains is imperative to ensure optimal operation. This includes periodic inspection for wear and tear, proper lubrication, and timely replacement of worn components. Following a maintenance schedule can prolong the life of the trencher chain and ultimately lead to improved efficiency in trenching operations.