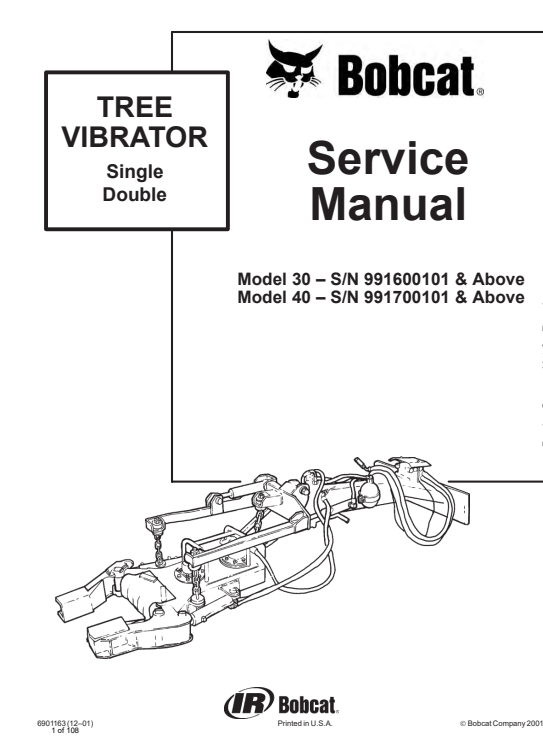

Bobcat Tree Vibrator Service Repair Manual

$5.00

Description

Package Include

Bobcat Tree Vibrator Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-108

Publication Number

6901163

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 39 mb

Compatible Machine Model : Bobcat Tree Vibrator

Compatible Serial Numbers :

Model 30 – S/N 991600101 & Above

Model 40 – S/N 991700101 & Above

Understanding the Bobcat Tree Vibrator: Features and Functionality

The Bobcat Tree Vibrator is a specialized piece of equipment designed to enhance efficiency in tree harvesting and landscaping operations. Its robust design enables it to shake and loosen trees from their roots, facilitating easier extraction or relocation. The fundamental components of this device typically include a hydraulic motor, vibration head, and adjustable mounting system, all of which contribute to its effectiveness in tree care tasks.

One of the most significant features of the Bobcat Tree Vibrator is its power-to-weight ratio, ensuring that even smaller trees can be effectively vibrated while maintaining fuel efficiency. It is engineered to work seamlessly with various Bobcat models, making it a versatile attachment for professionals in the industry. This compatibility allows users to switch between different types of tasks without needing multiple pieces of costly equipment.

Moreover, the functionality of the Bobcat Tree Vibrator extends beyond simply uprooting trees. By using vibrations, it can also stimulate root growth and promote plant health, which is crucial in landscaping projects. Utilizing this tool allows landscape professionals to achieve healthier trees and shrubs while streamlining their workflow. The vibration mechanism reduces the amount of manual labor required when compared to traditional methods, significantly increasing job efficiency.

Multiple models of the Bobcat Tree Vibrator are available, each with distinct specifications tailored to different operational needs. These models vary in terms of power output, weight capacity, and vibrations per minute, allowing users to select the most suitable option for their specific applications. The benefits of utilizing a Bobcat Tree Vibrator, as opposed to alternative methods, include faster processing times, reduced labor costs, and enhanced overall productivity.

Essential Repair and Maintenance Guidelines for Bobcat Tree Vibrators

Bobcat Tree Vibrators are essential tools for efficiently removing trees and stumps, and their proper maintenance ensures optimal performance and longevity. To keep your equipment in top condition, follow these essential repair and maintenance guidelines.

Routine maintenance is critical for preventing issues before they escalate. Begin by regularly checking and cleaning the vibration mechanism to remove debris that can impede functionality. Inspect the hydraulic hoses and connections for any signs of leaks or wear. Tightening loose connections and replacing worn-out hoses can prevent further damage. The hydraulic fluid should also be checked and changed as per the manufacturer’s recommendations to maintain appropriate pressure and fluidity.

When troubleshooting common issues, always start with a basic analysis. If the vibrators are not functioning effectively, verify the hydraulic pressure and ensure that the correct attachments are fitted properly. Listen for unusual sounds during operation, as they often indicate mechanical issues. For electrical components, use a multimeter to check for proper voltage supply and connectivity.

In the event of repairs, refer to the specific service manual for step-by-step instructions tailored to your model. This resource provides detailed guidance on replacing parts, recalibrating the machinery, and troubleshooting specific fault codes. Always utilize original manufacturer parts to maintain compatibility and performance.

To enhance the lifespan of your Bobcat Tree Vibrator, implement proactive practices such as conducting visual inspections after each use and storing the equipment in a dry, sheltered area during periods of inactivity. Furthermore, recognize early signs of wear—such as inconsistent vibrations or diminished performance—as indications that immediate action is necessary.

It is vital to adhere to safety precautions during maintenance and repairs. Always disconnect the power source before performing any maintenance tasks, and use protective gear to safeguard against potential hazards. If you encounter complexities beyond your expertise, do not hesitate to seek professional assistance, ensuring reliable repairs and ongoing equipment efficiency.