Bobcat Tilt-Tatch Service Repair Manual

$5.00

Description

Package Include

Bobcat Tilt-Tatch Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-46

Publication Number

6904266

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 5 mb

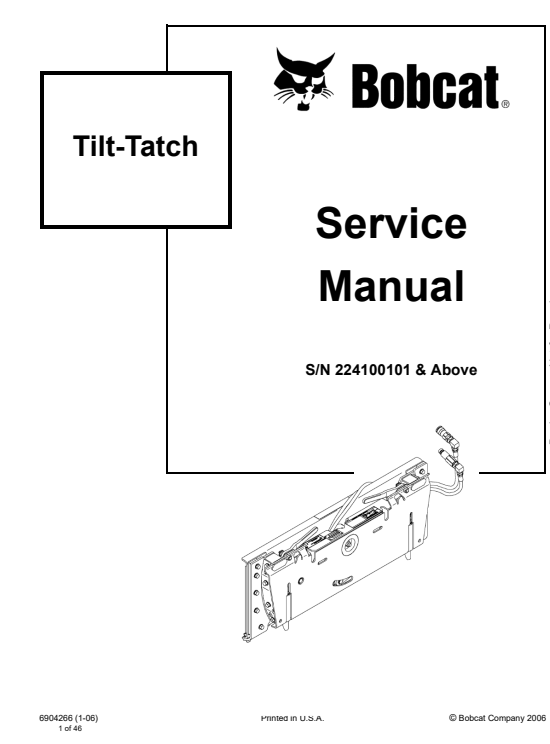

Compatible Machine Model : Bobcat Tilt-Tatch

Compatible Serial Numbers : S/N 224100101 & Above

Understanding the Bobcat Tilt-Tatch System

The Bobcat Tilt-Tatch system is a sophisticated mechanism designed to enhance the functionality and versatility of Bobcat machinery. Its primary purpose is to allow operators to perform a variety of tasks more efficiently by providing an adjustable angle for attachments. This feature is immensely beneficial in scenarios where precise control and flexibility are necessary, such as grading, leveling, or loading materials. By enabling operators to tilt their attachments, the Tilt-Tatch system significantly improves productivity on job sites.

Central to the Tilt-Tatch system are several key components, including the hydraulic tilt cylinders, pivot points, and the control mechanism. The hydraulic tilt cylinders are responsible for moving the attachment forward and backward, while the pivot points ensure that the attachment can rotate freely without compromising the stability of the machinery. The control mechanism, typically governed by the operator’s controls within the cabin, allows for precise manipulation of the attachment’s angle, ensuring optimal performance in various tasks.

In addition to its ease of use, the Tilt-Tatch system offers multiple benefits in terms of efficiency and effectiveness. The ability to adjust the attachment’s angle quickly can lead to time savings on projects, as operators do not need to unmount and remount attachments for minor changes in positioning. Furthermore, it reduces the physical strain on operators, minimizing the risk of accidents and injuries. However, like any mechanical system, the Tilt-Tatch is subject to wear and tear. Common issues may arise from hydraulic leaks, component misalignment, or wear at key pivot points, which can impact performance and safety. Therefore, regular maintenance and timely repairs are crucial to ensuring the longevity and reliability of the Tilt-Tatch system, making it a vital consideration for Bobcat equipment users.

Step-by-Step Guide for Service and Repair

The Bobcat Tilt-Tatch system is essential for maximizing the versatility of your Bobcat equipment. Proper servicing and repair can extend the lifespan of this important component while ensuring optimal functionality. This step-by-step guide aims to equip Bobcat owners and operators with the knowledge to perform maintenance effectively. To begin, gather the necessary tools, which typically include a socket set, wrenches, screwdrivers, pliers, and a torque wrench. In addition, safety gear such as gloves, goggles, and appropriate clothing should be worn to prevent any injuries during the repair process.

Before starting any repair work, it is crucial to ensure that the Bobcat equipment is off and securely parked on a stable surface. Begin the diagnostic process by inspecting the Tilt-Tatch system for visible signs of wear or damage. Common issues may include hydraulic fluid leaks, loose bolts, or malfunctioning hydraulic cylinders. If hydraulic issues are suspected, check fluid levels and inspect for any obstructions in the hydraulic lines.

Once you have identified any problems, it is essential to perform routine maintenance. This includes lubricating connectors and joints and tightening any loose bolts, as this can prevent further issues down the line. For more advanced repairs, such as replacing hydraulic components, follow the manufacturer’s specifications carefully to avoid any misalignment that could impact performance.

Throughout the repair process, it may be helpful to refer to visual aids or diagrams included in the Bobcat service manual. These resources can provide insight into specific components and assist in the proper disassembly and reassembly of the Tilt-Tatch system. Being thorough in this process will ensure your Bobcat Tilt-Tatch remains in optimal condition, minimizing the risk of future failures.