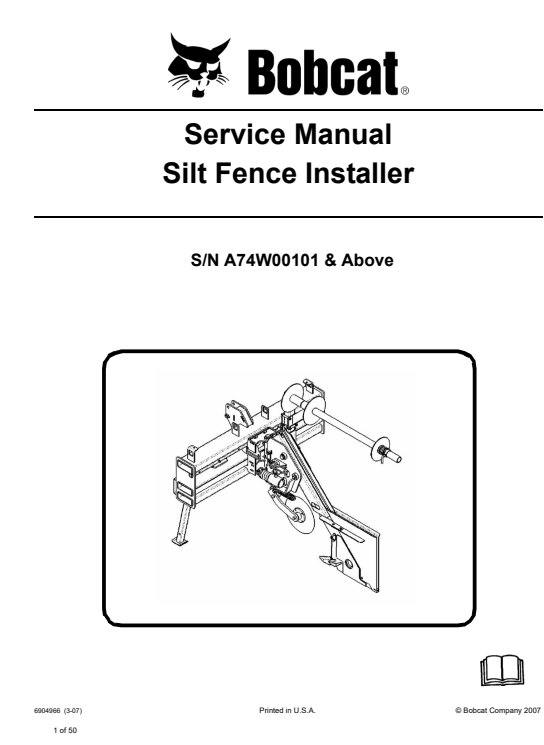

Bobcat Silt Fence Installer Service Repair Manual

$5.00

Description

Package Include

Bobcat Silt Fence Installer Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-50

Publication Number

6904966

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 8 mb

Compatible Machine Model :Bobcat Silt Fence Installer

Compatible Serial Numbers : S/N A74W00101 & Above

Understanding Bobcat Silt Fence Installers

A Bobcat silt fence installer is a specialized piece of construction equipment designed to create effective barriers for controlling sediment runoff during construction activities. Its primary purpose is to prevent soil erosion and protect nearby water bodies from contamination caused by construction debris and sediment. Bobcat’s silt fence installers are favored in both construction and environmental management settings due to their distinctive functionalities and robust design.

These installers are commonly used in a variety of projects, including residential, commercial, and infrastructure developments. In areas where soil stabilization is critical, such as during grading, excavation, and landscaping, the deployment of silt fences is essential. By intercepting sediment-laden water, these barriers maintain compliance with environmental regulations, safeguarding ecosystems and ensuring responsible land management.

The benefits of using Bobcat equipment for silt fence installation are noteworthy. Bobcat machines are renowned for their reliability, ease of use, and efficiency. Operators can quickly and precisely install silt fences, minimizing disruption to the project site. Furthermore, Bobcat silt fence installers come equipped with features such as adjustable heights and durable materials, enhancing their adaptability to various project requirements and terrain types.

What sets Bobcat silt fence installers apart from other brands is their commitment to innovation and quality. The design and engineering of these machines focus on user-friendliness and operational performance, allowing for a smoother installation process. This is crucial, as proper installation is fundamental to achieving effective erosion control. Inadequate or improper installation could lead to failure in sediment containment, underlining the importance of choosing a reliable and efficient silt fence installer.

Service and Repair Manual for Bobcat Silt Fence Installers

The efficient operation of Bobcat silt fence installers is crucial for maintaining effective sediment control on construction sites. Routine maintenance and timely repairs are essential to ensure optimal performance and longevity of these machines. Following a structured servicing schedule can prevent unexpected breakdowns and extend the operational lifespan of the equipment.

It’s important to identify common issues that may arise during the use of Bobcat silt fence installers. Typical problems include hydraulic leaks, wear on the silt fence installation components, and electrical malfunctions. Regular inspections can help in early detection of these issues. Operators should be trained to recognize signs of wear, such as diminished functionality or unusual noises, which may indicate the need for repair.

When troubleshooting problems, step-by-step guidance can greatly assist operators. Begin by consulting the equipment manual for specific troubleshooting charts. These charts provide clarity on diagnostic procedures. For instance, if hydraulic pressure is inadequate, checking for leaks and ensuring fluid levels are conducive to functionality should be the first steps. Additionally, inspecting filters and connections is crucial in addressing low hydraulic performance.

Replacement of worn or damaged parts is a significant aspect of maintaining Bobcat silt fence installers. Operators should ensure they procure original parts from authorized dealers, as using generic components may compromise functionality. It’s advisable to keep a stock of vital spare parts to reduce downtime during repairs. Comprehensive maintenance practices also involve cleaning and lubricating moving parts regularly to prevent premature wear.

Operators should always prioritize safety while performing maintenance tasks. Wearing appropriate protective equipment, following lockout/tagout procedures, and being aware of your surroundings are critical best practices that should be observed during service and repair activities. By adhering to these protocols, operators can maintain the integrity of their equipment while ensuring a safe working environment.