Bobcat Hydraulic Breaker Service Repair Manual

$5.00

Description

Package Include

Bobcat Hydraulic Breaker Service Repair Manual

Language

English

Format

PDF

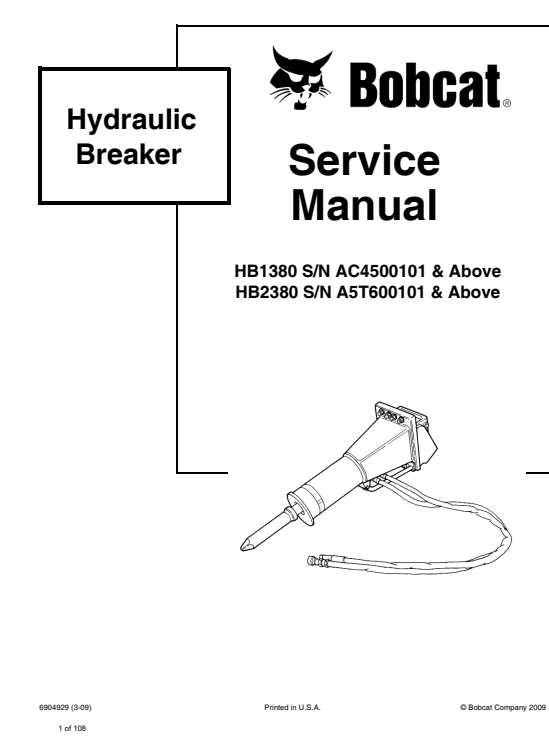

Total Number of pages

1-108

Publication Number

6904929

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 18 mb

Compatible Machine Model : Bobcat Hydraulic Breaker

Compatible Serial Numbers :

HB1380 S/N AC4500101 & Above

HB2380 S/N A5T600101 & Above

Understanding the Bobcat Hydraulic Breaker

The Bobcat hydraulic breaker serves as a vital attachment for various Bobcat equipment, delivering powerful performances during demolition and construction tasks. Its primary purpose is to break concrete, asphalt, and other tough materials, making it an essential tool for contractors and construction workers. The hydraulic breaker utilizes hydraulic pressure to deliver strong, controlled impacts to break apart the materials efficiently.

There are different types of hydraulic breakers available specifically designed for use with Bobcat machinery. Each type varies in size, weight, and specifications, catering to the diverse needs of projects. Lightweight models are ideal for smaller Bobcat machines, while heavier options are suited for larger, more robust models. This versatility ensures that operators can select the suitable breaker for their specific tasks, enhancing performance and productivity.

Compatibility with various Bobcat models is a notable aspect that operators must consider when choosing a hydraulic breaker. It is crucial to match the attachment to the specific machine to ensure optimal functionality. Many hydraulic breakers have been engineered to seamlessly integrate with Bobcat equipment, allowing for easy installation and operation. This compatibility extends to various Bobcat series, making it easier for operators to switch between tools as needed without compromising efficiency.

Proper maintenance of the Bobcat hydraulic breaker is essential to ensure its longevity and sustained performance. By adhering to maintenance schedules, operators can keep the attachment in peak condition, reducing the chances of breakdowns and costly repairs. Regular inspections and servicing can significantly enhance the attachment’s productivity on job sites, enabling workers to complete projects more effectively.

Service and Repair Fundamentals

Maintaining and servicing Bobcat hydraulic breakers is essential to ensure optimal performance and longevity. Regular maintenance helps prevent common issues such as decreased efficiency, leakage, and operational failure. The first step in any service task is to consult the official Bobcat hydraulic breaker service repair manual. This document provides crucial specifications and guidelines that streamline the repair process and ensure compliance with manufacturer standards.

Routine maintenance procedures include checking the hydraulic fluid levels, inspecting hoses for wear or leaks, and replacing worn-out components. Using the right tools is vital; a variety of hand tools, such as wrenches, pliers, and screwdrivers, are typically required for most repairs. It’s essential to have safety gear, including gloves and eye protection, when working on equipment to prevent accidents and injuries.

During operation, users may encounter common issues such as inadequate power or the breaker not functioning properly. Troubleshooting these issues can involve checking the hydraulic system for blockages, ensuring that the breaker is properly connected, and examining the operating pressure settings. In cases of significant malfunction, referring to the service manual for troubleshooting guidelines is recommended to accurately diagnose the problem.

Replacement parts, such as seals, pistons, and adapters, should be sourced from reputable suppliers to maintain the integrity of the hydraulic breaker. Using non-genuine parts can affect performance and may void warranties. Proper servicing not only extends the life of the hydraulic breaker but also enhances productivity on the job site. Following the detailed instructions laid out in the service repair manual, along with diligent adherence to safety precautions and proper technique, can empower users to confidently undertake service and repair tasks.