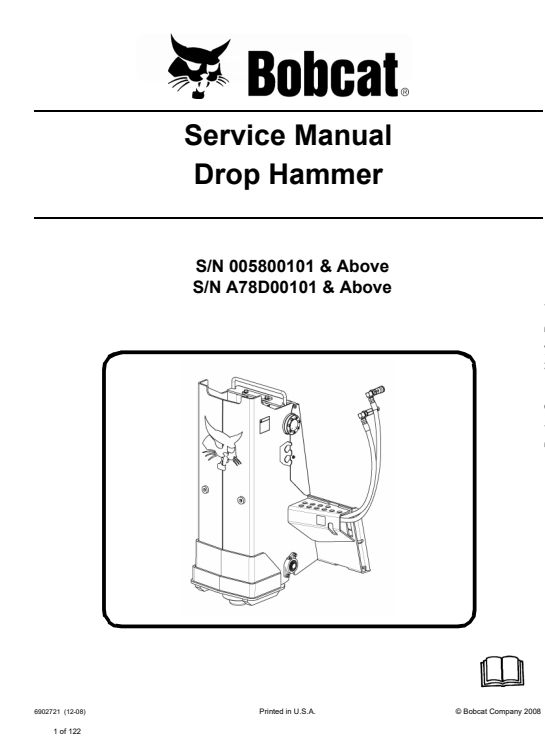

Bobcat Drop Hammer Service Repair Manual

$5.00

Description

Package Include

Bobcat Drop Hammer Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-122

Publication Number

6902721

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 18 mb

Compatible Machine Model : Bobcat Drop Hammer

Compatible Serial Numbers :

S/N 005800101 & Above

S/N A78D00101 & Above

Understanding the Bobcat Drop Hammer

The Bobcat Drop Hammer is a significant piece of equipment widely used in the construction and demolition industries. This hydraulic attachment is designed to deliver powerful, controlled impacts on various surfaces, making it highly effective for breaking concrete, compacting soil, and driving stakes or pilings. Its versatility allows it to be mounted on various Bobcat loaders, enhancing the efficiency of machines already utilized in construction settings.

The operation of the Bobcat Drop Hammer is based on a straightforward principle. It utilizes gravitational force to drop a heavy hammer onto the targeted material, generating immense impact energy. This force effectively fractures difficult materials, allowing for demolition tasks to be completed faster than would be possible with traditional methods. The design of the drop hammer incorporates a durable cylinder and mechanism, ensuring longevity and reliability during operation.

One of the primary benefits of the Bobcat Drop Hammer over other equipment is its ability to perform precision tasks with reduced noise and vibration. This feature is particularly valuable in urban settings where minimizing disturbance is critical. Additionally, the drop hammer’s design allows for the effective use of hydraulic power, which translates to greater force and efficiency compared to manually operated tools.

Moreover, the Bobcat Drop Hammer is integral in various applications, ranging from road construction to landscaping. It can be utilized in projects where traditional demolition tools may prove ineffective, such as within confined spaces or soft ground conditions. This broad range of applications underscores the importance of understanding the mechanics and functions of the Bobcat Drop Hammer, ultimately contributing to enhanced project efficacy in the heavy machinery landscape.

Service and Repair Guidelines for the Bobcat Drop Hammer

The Bobcat Drop Hammer is a vital piece of equipment used in various construction and demolition projects, and maintaining its operational efficiency is crucial for safety and productivity. Adhering to the service and repair guidelines outlined in the Bobcat Drop Hammer service manual is essential for users looking to keep their machinery in peak condition. Regular maintenance practices, including inspections and timely service interventions, can prevent unforeseen breakdowns and extend the lifespan of the equipment.

To begin with, routine maintenance should include checking hydraulic fluids, inspecting hoses for wear and tear, and ensuring that all connections remain secure. Users must also periodically examine the drop hammer’s striking mechanism, as accumulation of debris can impair its function. Addressing small issues promptly can prevent more significant complications down the line.

Troubleshooting tips are also critical; users may occasionally experience decreased performance from the drop hammer. Common issues might include inadequate striking power or inaccurate depth performance. In such cases, users are advised to consult the troubleshooting section of the service manual, which typically provides a systematic approach to diagnosing and resolving these problems effectively.

When repairs are necessary, the service manual provides step-by-step instructions that outline the process clearly. Having the correct tools, such as wrenches, socket sets, and hydraulic jacks, is essential for executing repairs safely. Safety precautions, including wearing protective gear and ensuring the machine is powered down during maintenance, should always be a priority to mitigate risks associated with working on heavy equipment.

It is also imperative to source authentic parts for any replacements, as using counterfeit components can lead to further complications. Bobcat authorized dealers are the best resources for obtaining genuine parts and additional service assistance. Following these guidelines not only enhances the performance of the Bobcat Drop Hammer but also ensures user safety and machinery longevity.