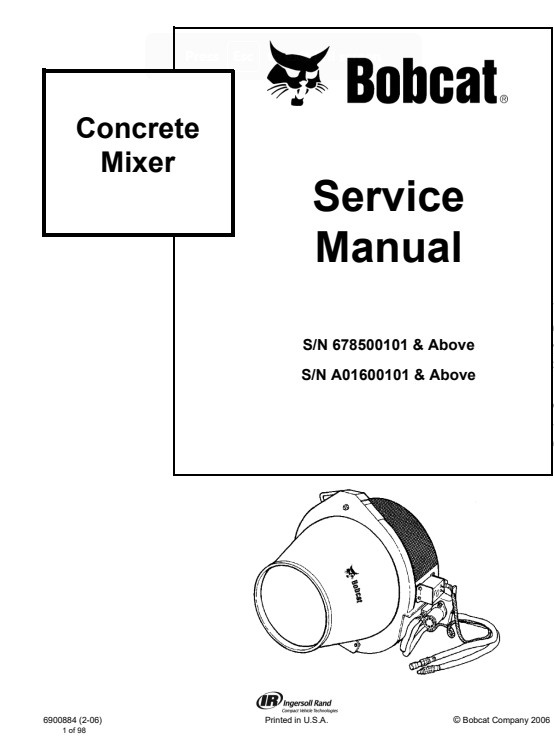

Bobcat Concrete Mixer Service Repair Manual

$5.00

Description

Package Include

Bobcat Concrete Mixer Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-98

Publication Number

6900884

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 52 mb

Compatible Machine Model :Bobcat Concrete Mixer

Compatible Serial Numbers :

S/N 678500101 & Above

S/N A01600101 & Above

Understanding Bobcat Concrete Mixer Components

The Bobcat Concrete Mixer comprises several essential components that work in harmony to facilitate the effective mixing of concrete. Each part plays a significant role in ensuring the machine operates efficiently and delivers high-quality results. Key components include the engine, transmission, hydraulic system, mixing drum, and electronic elements.

The engine serves as the powerhouse of the mixer, providing the necessary energy to drive other components. Typically, Bobcat concrete mixers are equipped with robust engines designed to handle the demands of concrete mixing. Periodic maintenance of the engine, such as oil changes and filter replacements, is crucial for performance and longevity.

Next, the transmission allows for the transfer of power from the engine to the mixer. It regulates the speed and torque, ensuring the machine can adapt to various mixing requirements. Regular checks on the transmission fluid levels and prompt addressing of any leaks will help maintain its optimal performance.

The hydraulic system plays an essential role in controlling the movement of various components, including the mixing drum. This system ensures that the drum can rotate at the appropriate speed for thorough mixing, while also facilitating the tipping mechanism for unloading. Keeping hydraulic fluids at the correct levels and inspecting hoses for wear can prevent breakdowns.

The mixing drum is where the actual mixing process occurs. Designed with a specific shape and size, it allows for thorough blending of materials. Regular cleaning of the drum after use prevents build-up and contamination, which can affect mixing quality. Additionally, operators should watch for signs of wear, such as cracks or deformations, which may necessitate prompt replacement.

Finally, electronic components, including controls and sensors, are integral for the operation and safety of the mixer. Ensuring that all electrical connections are secure and monitoring indicator lights can prevent potential issues. Regular inspections and tests of these components are crucial to maintaining reliability.

Step-by-Step Repair and Maintenance Procedures

The maintenance and repair of Bobcat Concrete Mixers are essential to ensure their optimal performance and longevity. Adhering to the guidelines provided in the service manual will assist operators in executing these tasks efficiently. The process begins with routine maintenance, which includes checking and changing the engine oil regularly. It is recommended to change the oil every 100 operating hours to prevent engine wear. To perform this, gather the necessary tools, including a wrench, oil filter wrench, and a drain pan. Carefully remove the old oil using the drain plug and replace it with fresh oil according to the specifications outlined in the manual.

Additionally, hydraulic fluid levels should be checked frequently. Low hydraulic fluid can lead to reduced performance and potential pump damage. The fluid reservoir should be inspected for leaks, and any low levels should be topped up with the recommended hydraulic fluid. Replacing the hydraulic filters at specified intervals is crucial to prevent contamination and ensure proper flow. To replace the filter, locate the filter housing, remove the old filter, and install a new one, ensuring all seals are secure.

When it comes to common repairs, troubleshooting engine issues is a critical task. Begin by checking the battery charge and the connections. Inspect the fuel lines for leaks and ensure the fuel filter is clean. Should the engine fail to start, pay attention to potential electrical problems, which may involve checking fuses or wiring. Hydraulic leaks can generally be identified by fluid puddles beneath the mixer, and these can often be fixed by replacing worn seals or hoses.

Safety precautions cannot be overstated. Operators should wear appropriate personal protective equipment, and always disconnect the battery before commencing repairs. Following these step-by-step procedures will not only enhance the reliability of the Bobcat Concrete Mixer but also extend its operational lifespan.