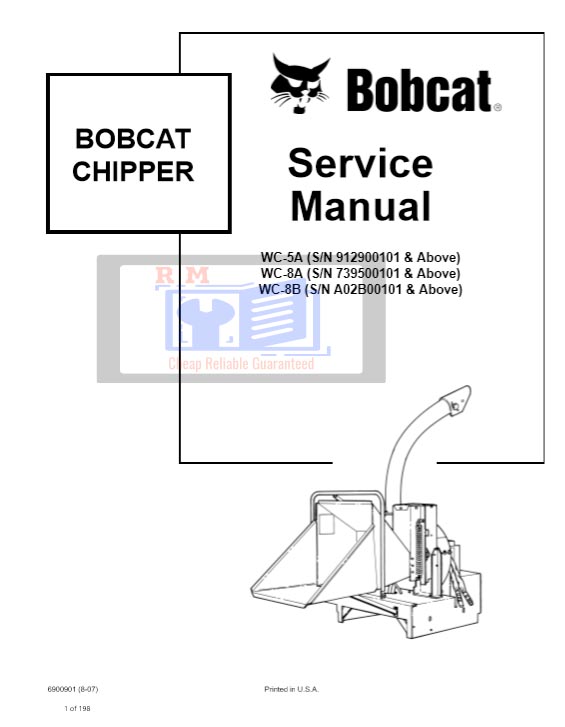

Bobcat Chipper WC5A WC8A WC8B Service Repair Manual

$25.00

BEFORE YOU BUY FULL PDF MANUAL, PLEASE DOWNLOAD SAMPLE OF THIS PDF MANUAL AND PLEASE CHECK IT IS COMPATIBLE WITH YOUR MODEL

Description

Package Include

Bobcat Chipper WC5A WC8A WC8B Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-198

Publication Number

6900901 [8-7]

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 9 mb

With This Service Repair Manual The Technician can solve any problems encountered in the operation of your Bobcat Chipper Models of :

WC5A [SN 912900101 & Above]

WC8A [SN 739500101 & Above]

WC8B [SN A02B00101 & Above]

The Bobcat wood chipper attachment grinds branches, trees and limbs, reducing branch volume 10 to 1. Unlike a pull-type wood chipper, the wood chipper attachment can easily be placed into backyards and remote areas with the manoeuvrability of a Bobcat loader. Hydraulic power feed is included as standard equipment.

A wood chipper (also known as tree chipper) is a machine that is used to cut tree limbs, trunks, and branches into chips. They make cleaning up after vegetation maintenance a lot less arduous.

How does a log chipper work?

Most woodchippers rely on energy stored in a heavy flywheel to do their work (although some use drums). The chipping blades are mounted on the face of the flywheel, and the flywheel is accelerated by an electric motor or internal combustion engine.

What is the difference between a wood chipper and a wood shredder?

Need a Wood Chipper? Here’s What to Know Before You Buy

The difference between a wood chipper and a wood shredder is how they break down material. While chippers break down branches and larger limbs, shredders will work on smaller vegetation debris, like leaves, making mulch and compost. Chipper Shredder: Combines the functions of shredding and chipping.

TO CONFIRM IS THIS SERVICE MANUAL COMPATIBLE WITH YOUR MACHINE MODEL PLEASE DOWNLOAD SAMPLE

[the_ad id=”23726″]

Introduction to Bobcat Chippers WC5A, WC8A, and WC8B

Bobcat chippers, including the models WC5A, WC8A, and WC8B, stand out as vital tools in the landscape management and forestry industries. These machines are specifically engineered to efficiently chip branches and other woody materials, converting them into smaller wood chips that can be reused or disposed of conveniently. Each model in this series boasts distinct specifications tailored to various operational needs. For instance, the WC5A is suited for lighter duty applications, while the WC8A and WC8B are designed for more demanding tasks, offering greater capacity and robust performance.

In addition to their different capabilities, these chippers are equipped with key features such as heavy-duty cutting blades, adjustable infeed openings, and user-friendly controls. These attributes enhance their functionality, allowing operators to work effectively across diverse environments—from parks and residential yards to large forestry operations. Proper understanding of these machines’ functionalities ensures effective operation, leading to time and cost savings during usage.

Regular maintenance and servicing are crucial for ensuring that Bobcat chippers perform at their best. By adhering to scheduled maintenance routines, operators can prolong the operational lifespan of their machines and reduce the likelihood of malfunctions. A comprehensive service and repair manual is an essential resource for both operators and technicians. This manual provides detailed insights into each machine’s components, recommended maintenance practices, and troubleshooting techniques. Having access to these guidelines not only contributes to equipment longevity but also enhances safety by fostering informed operation and repair practices. Understanding the importance of maintenance not only benefits the equipment but serves to ensure overall productivity in chipper operations.

Service and Repair Procedures

When servicing and repairing Bobcat chippers WC5A, WC8A, and WC8B, it is essential to follow clear, structured procedures to ensure efficiency and safety. Regular maintenance tasks play a crucial role in the longevity and performance of these machines. Operators should regularly check the engine oil levels, air filters, and blade sharpness as a part of routine upkeep. To begin servicing, ensure the machine is turned off and disconnected from any power source. This is critical for operator safety.

One common maintenance task involves inspecting and sharpening the blades. To do this, carefully remove the cover and the blades from the chipper. Use appropriate safety gear, including gloves and eye protection. Inspect the blades for damage or dullness. If they require sharpening, utilize a bench grinder or sharpening tools suitable for the material. After sharpening, reassemble the components in the correct order, making sure to tighten all fasteners to the manufacturer’s recommended torque specifications.

Troubleshooting frequent issues with Bobcat chippers is equally important. For instance, if the chipper is not operating efficiently, check for blockages in the feed mechanism or the chute. Foreign objects can impede the flow of materials, leading to mechanical strain. The hydraulic system should also be inspected for leaks or abnormalities in pressure. Use compatible hydraulic fluid and replace it according to the maintenance schedule specified in the user manual.

When dealing with the engine, always refer to the specific manual for the engine model used in the Bobcat chipper. Regularly scheduled oil changes and filter replacements will ensure optimal engine performance. It is also recommended to keep an organized toolbox with the necessary tools, including wrenches, socket sets, and screwdrivers, to facilitate repairs.

By adhering to these service and repair procedures, operators can maintain the efficiency of their Bobcat chippers and prolong their operational lifespan effectively and safely.