Overview of Bobcat Mini Excavators

Bobcat mini excavators, particularly the models 320, 320L, and 322, are renowned for their exceptional performance and reliability in various industries such as construction and landscaping. These machines are designed to deliver superior digging efficiency while ensuring ease of maneuverability in confined spaces. The compact nature of these mini excavators makes them the preferred choice for operators working on residential projects or urban construction sites where space is a premium.

The Bobcat 320 and 320L models are equipped with robust engines that provide substantial power despite their smaller size. Both machines feature a maximum operating weight of approximately 3,000 to 4,000 pounds, allowing them to perform a variety of tasks efficiently. The Bobcat 322, a slightly larger model, offers increased lift capacity and digging depth capabilities, making it suitable for heavier applications while maintaining the same compact design that enhances its versatility.

One of the key selling points of these mini excavators is their user-friendly controls and intuitive design, which reduce the learning curve for new operators. With features such as advanced hydraulic systems and enhanced stability, users can operate the machinery with confidence, whether they are engaged in digging trenches, demolishing structures, or landscaping tasks. Additionally, the safety features integrated into Bobcat mini excavators ensure that operators can work effectively while minimizing the risk of accidents.

The significance of Bobcat mini excavators in modern construction and landscaping cannot be overstated. Their ability to perform multiple functions—ranging from excavation to lifting and grading—makes them invaluable assets for contractors and landscapers alike. In summary, the combination of compact design, robust performance, and ease of use positions Bobcat 320, 320L, and 322 mini excavators as top choices for professionals seeking efficiency and reliability in their projects.

Wiring Schematic Analysis for Bobcat 320, 320L, and 322

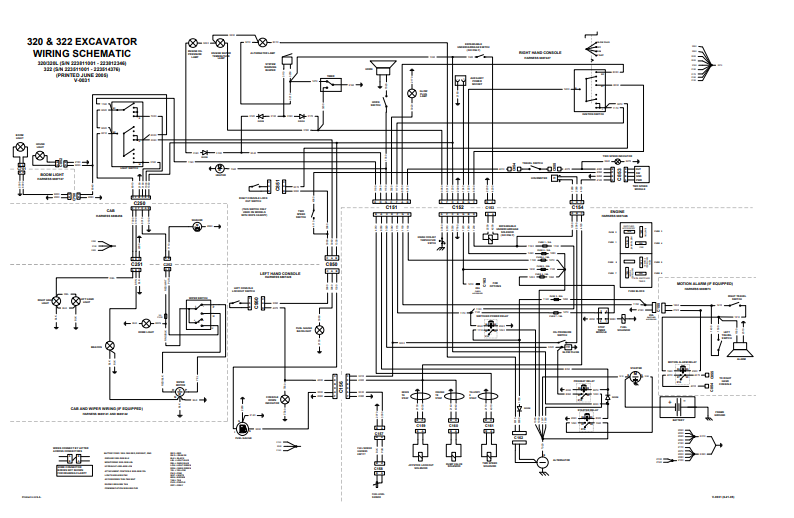

The wiring schematic serves as a crucial component in understanding the operational and maintenance aspects of the Bobcat 320, 320L, and 322 mini excavators. These models are equipped with complex electrical systems, and the wiring schematic provides a graphical representation of the electrical layout. It details the interconnections between various components, such as sensors, relays, and connectors, facilitating effective communication within the machine.

In these excavators, the wiring schematic maps out essential elements like the control systems, which direct the functionalities of the machine. For instance, sensors are instrumental in monitoring critical parameters such as temperature and pressure, sending signals to the control unit for optimal machine performance. Relays act as switches, enabling the control circuitry to manage high-power devices without compromising safety. Similarly, connectors are vital for establishing secure connections among wiring, ensuring seamless operation of the electrical systems. Each of these components plays a pivotal role in the overall functionality, impacting how power is distributed throughout the machine.

Operators should be cognizant of common wiring issues that may occur, such as loose connections or frayed wires. Troubleshooting these problems starts with consulting the wiring schematic to trace the affected circuits. For example, if the machine experiences power loss, examining the wiring for damaged connectors or relays can lead to identifying the root cause. Additionally, regular checks of the schematic during maintenance can preemptively address potential wiring failures, thus enhancing the longevity and reliability of the excavators. Furthermore, ensuring that connections are clean and secure can prevent electrical interruptions that impact performance, making it essential for operators to be familiar with the wiring details for effective maintenance and repair.