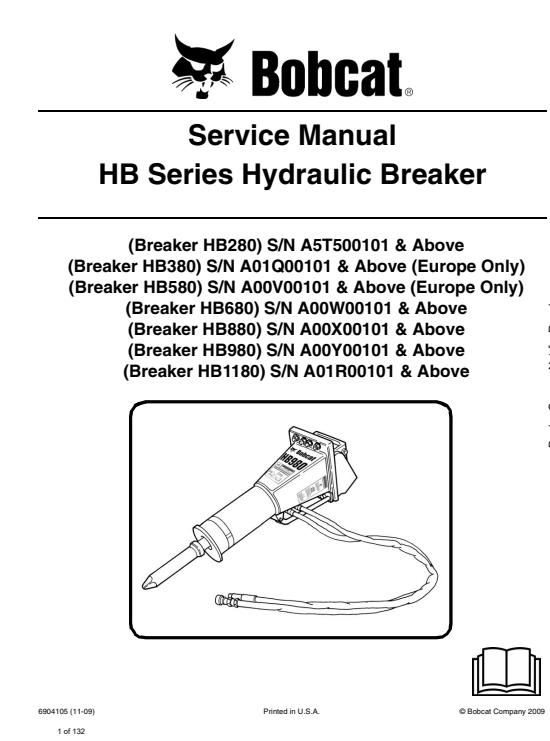

Bobcat HB Series Hydraulic Breaker Service Repair Manual

$5.00

Compatible Machine Model :Bobcat HB Series Hydraulic Breakers

Compatible Serial Numbers :

(Breaker HB280) S/N A5T500101 & Above

(Breaker HB380) S/N A01Q00101 & Above (Europe Only)

(Breaker HB580) S/N A00V00101 & Above (Europe Only)

(Breaker HB680) S/N A00W00101 & Above

(Breaker HB880) S/N A00X00101 & Above

(Breaker HB980) S/N A00Y00101 & Above

(Breaker HB1180) S/N A01R00101 & Above

BEFORE YOU BUY FULL PDF MANUAL, PLEASE DOWNLOAD SAMPLE OF THIS PDF MANUAL AND PLEASE CHECK IT IS COMPATIBLE WITH YOUR MODEL

Description

Package Include

Bobcat HB Series Hydraulic Breaker Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-132

Publication Number

6904105

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 16 mb

Compatible Machine Model :Bobcat HB Series Hydraulic Breakers

Compatible Serial Numbers :

(Breaker HB280) S/N A5T500101 & Above

(Breaker HB380) S/N A01Q00101 & Above (Europe Only)

(Breaker HB580) S/N A00V00101 & Above (Europe Only)

(Breaker HB680) S/N A00W00101 & Above

(Breaker HB880) S/N A00X00101 & Above

(Breaker HB980) S/N A00Y00101 & Above

(Breaker HB1180) S/N A01R00101 & Above

Overview of Bobcat HB Series Hydraulic Breakers

The Bobcat HB Series Hydraulic Breakers are advanced tools designed specifically for construction and demolition tasks, offering exceptional power and performance. One of the primary features of the HB Series is its ability to deliver high impact energy while maintaining a favorable power-to-weight ratio. This design ensures that operators can efficiently perform heavy-duty breaking work without the need for larger, more cumbersome equipment.

Typically, the Bobcat HB Series finds its applications in a range of demolition tasks, including breaking concrete, asphalt, and other hard materials. These hydraulic breakers can be utilized for road repairs, trenching, and site preparation, showcasing their versatility across various construction environments. Additionally, they serve as an excellent solution for quarrying and mining operations, where precise and powerful striking capability is crucial.

One of the standout advantages of the HB Series is its durability, engineered to withstand demanding conditions while providing consistently high performance. The breakers are constructed from robust materials, ensuring longevity and minimal downtime for maintenance. Furthermore, their user-friendly design allows for easy installation and compatibility with a range of Bobcat machinery, including mini-excavators and skid-steers. The versatility of the models available within the HB Series caters to both novice operators and seasoned professionals, offering configurations suitable for different project needs.

Within the HB Series, there are several models, each with varying specifications that accommodate different job requirements. For instance, lighter models are ideal for more delicate tasks, while heavier options are designed for substantial demolition applications. This comprehensive selection ensures that users can select the optimal hydraulic breaker tailored to their specific operational demands.

Service and Repair Procedures for the HB Series Hydraulic Breakers

The effective maintenance of Bobcat HB Series Hydraulic Breakers plays a critical role in ensuring their long-term performance and reliability. Routine maintenance tasks should be prioritized to prevent unexpected breakdowns, which can lead to costly downtimes. First, operators should regularly check the hydraulic fluid levels; insufficient fluid can lead to overheating and reduced efficiency. It is recommended to inspect the condition of hydraulic fluid for contamination or degradation, as this affects the overall operation of the breaker.

Additionally, inspecting wear parts is vital for maintaining the functionality of the hydraulic breaker. Components such as chisels and bushings should be examined for signs of wear or damage. It is advisable to replace these parts as needed to ensure optimal performance, as worn components can result in inefficient operation and even damage to the breaker itself.

Cleaning the hydraulic breaker should also be a part of the routine maintenance schedule. This includes removing debris and build-up from the exterior and ensuring all grease points are properly lubricated. A clean breaker not only functions more effectively but also minimizes the risk of corrosion and premature wear.

For more complex repairs, it is essential to follow step-by-step instructions to disassemble the breaker safely. Operators should begin by isolating the equipment from the power source and relieving any hydraulic pressure. Once disassembled, operators should carefully inspect seals and pistons for wear or damage, replacing them as necessary. The reassembly process must be conducted with precision, ensuring all components are aligned correctly to avoid operational issues.

Throughout this process, safety protocols must be strictly adhered to. Proper personal protective equipment (PPE) should be worn, and the use of designated tools helps ensure tasks are carried out efficiently and safely. By following these service and repair procedures, operators can maintain the Bobcat HB Series Hydraulic Breakers effectively, ensuring their reliability and performance in various applications.