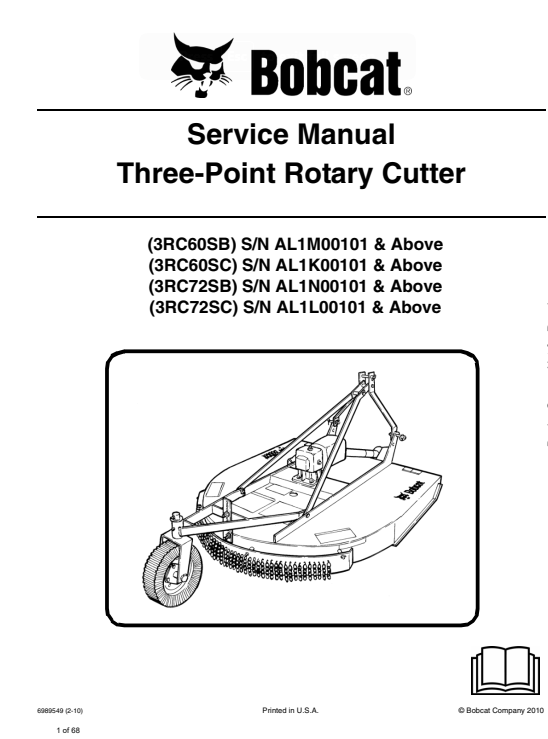

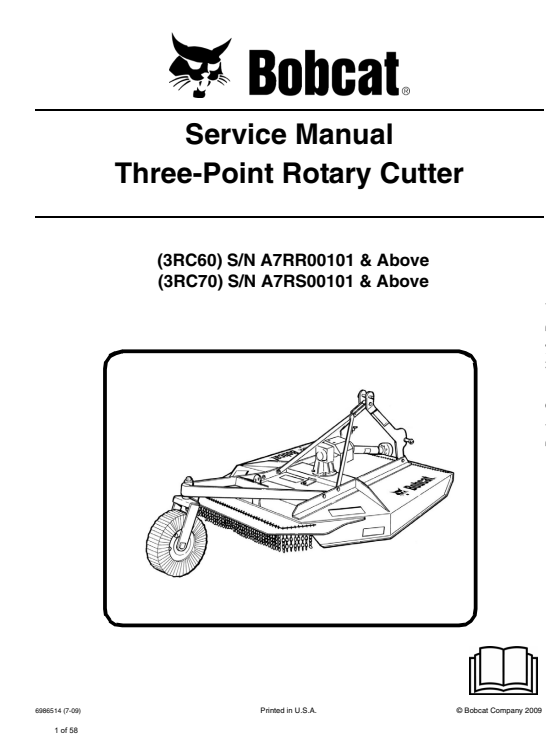

Bobcat Three Point Rotary Cutter Service Repair Manual

$5.00

Description

Package Include

Bobcat Three Point Rotary Cutter Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-58

Publication Number

6986514

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 7 mb

Compatible Machine Model :Bobcat Three Point Rotary Cutter

Compatible Serial Numbers :

(3RC60) S/N A7RR00101 & Above

(3RC70) S/N A7RS00101 & Above

Understanding Your Bobcat Three Point Rotary Cutter

The Bobcat Three Point Rotary Cutter is an essential tool for various landscaping and agricultural tasks, designed to deliver efficiency and precision. This implement attaches to the rear of a Bobcat loader or tractor, utilizing a three-point hitch system for stability and control. Primarily, the rotary cutter operates through a rotating blade mechanism, which is engineered to cut through vegetation, brush, and small trees with remarkable ease. These capabilities make it a perfect choice for farmers, landscapers, and property owners seeking to maintain their land effectively.

Key components of the Bobcat Rotary Cutter include the heavy-duty blades, cutting deck, and the drive system. The blades, typically made from hardened steel, rotate at high speeds to ensure a clean cut, minimizing the risk of damage to the machine and surrounding areas. The cutting deck, designed to withstand rugged conditions, allows for a wide cutting width, making it ideal for larger areas. Additionally, the drive system ensures that power is efficiently transmitted from the tractor or loader to the cutter, maximizing its operational performance.

When utilizing the Bobcat Three Point Rotary Cutter, operators will appreciate its advantages, such as versatility and ease of use. This equipment is capable of tackling various terrains, from flat fields to hilly landscapes, and can handle a range of vegetation types. Despite its robust design, users may occasionally encounter issues such as blade dullness, belt wear, or hydraulic problems, which can affect performance. Recognizing these common issues early can help mitigate further complications and potential downtime.

Regular maintenance is paramount to the longevity and performance of the Bobcat Three Point Rotary Cutter. By adhering to a consistent service schedule, users not only enhance the reliability of the cutter but also ensure optimal cutting results. In the subsequent sections, we will explore the specific service and repair procedures required to maintain this powerful tool in peak condition.

Service and Repair Procedures for the Bobcat Rotary Cutter

The Bobcat Three Point Rotary Cutter is a robust tool designed to manage thick grass, brush, and other vegetation. Regular maintenance is essential to ensure its longevity and performance. One of the fundamental service tasks is blade sharpening. Dull blades can result in uneven cutting, so it is crucial to check and sharpen them regularly. To sharpen the blades, follow these steps: first, disconnect the power source and ensure the unit is on a flat, stable surface. Next, remove the blade assembly according to the instructions in the service repair manual. Use a suitable sharpening tool to hone the edges, taking care to maintain the original angle of the blade. Once the sharpening is complete, reassemble the blade assembly properly before reconnecting the power.

Another critical maintenance task involves oil changes. The rotary cutter’s gearbox requires a regular oil change to function efficiently. To perform this task, first, drain the old oil, ensuring to dispose of it correctly. Check the service manual for the recommended oil type and refill with new oil, taking care not to overfill. Regular oil changes can prevent wear and prolong the life of the gearbox.

Belt adjustments are also necessary to ensure the cutter operates smoothly. Check the tension of the belts periodically; improper tension can lead to excessive wear or slippage. To adjust the belt tension, identify the adjustment screws specified in the service manual and make the necessary changes while ensuring proper tension is maintained for optimal performance.

Common problems, such as lack of power or uneven cutting, can often be traced back to either dull blades or incorrect belt tension. By regularly inspecting and maintaining the blades and belts, many issues can be avoided. Using the service repair manual effectively can help guide through troubleshooting steps and provide useful diagrams for identifying parts and processes, creating a thorough understanding of the maintenance and repair needed for the Bobcat Rotary Cutter.