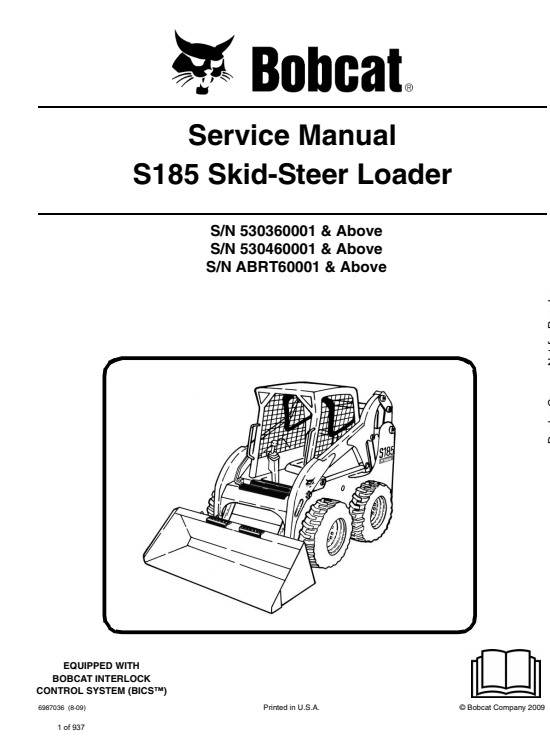

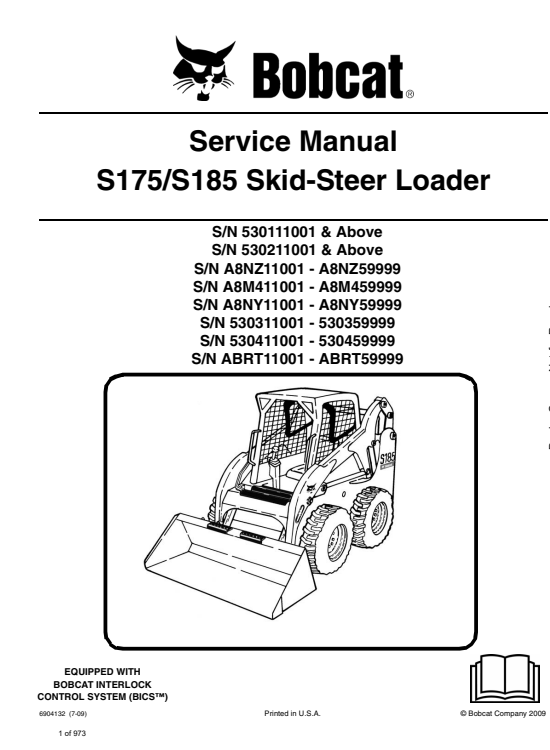

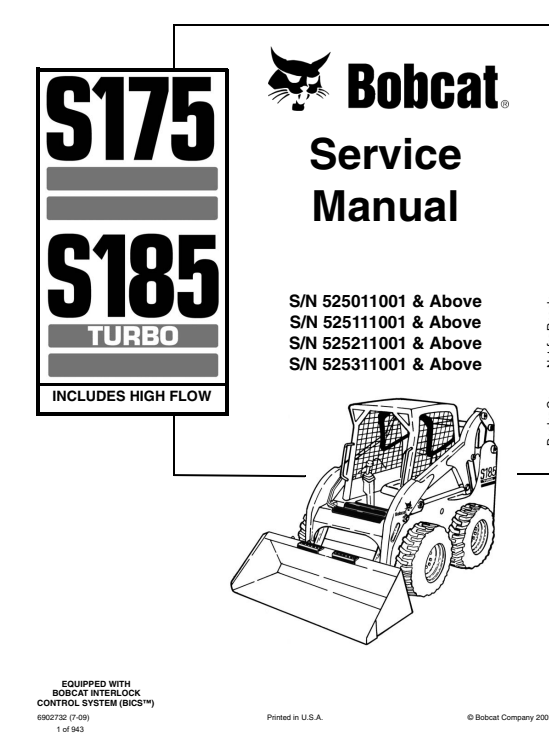

Bobcat S175, S185 Turbo SkidSteer Loader Service Repair Manual

$5.00

Compatible Machine Model :

Bobcat S175 Turbo SkidSteer Loader

Bobcat S185 Turbo SkidSteer Loader

Compatible Serial Numbers :

S/N 525011001 & Above

S/N 525111001 & Above

S/N 525211001 & Above

S/N 525311001 & Above

BEFORE YOU BUY FULL PDF MANUAL, PLEASE DOWNLOAD SAMPLE OF THIS PDF MANUAL AND PLEASE CHECK IT IS COMPATIBLE WITH YOUR MODEL

Description

Package Include

Bobcat S175, S185 Turbo SkidSteer Loader Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-943

Publication Number

6902732

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 279 mb

Compatible Machine Model :

Bobcat S175 Turbo SkidSteer Loader

Bobcat S185 Turbo SkidSteer Loader

Compatible Serial Numbers :

S/N 525011001 & Above

S/N 525111001 & Above

S/N 525211001 & Above

S/N 525311001 & Above

Introduction to Bobcat S175 and S185 Turbo Skid Steer Loaders

The Bobcat S175 and S185 Turbo Skid Steer Loaders represent cutting-edge machinery widely respected for their versatility and robust performance across diverse industries. These skid steers are designed for optimal maneuverability and power, making them indispensable in construction, landscaping, and agricultural applications. Equipped with turbocharged engines, these loaders deliver increased power and efficiency, crucial for tasks that demand both strength and speed.

The S175 model boasts a rated operating capacity of 1,750 pounds, while the S185 offers a slightly higher capacity of 1,850 pounds. This makes both models ideal for lifting heavy loads and tackling challenging terrains with ease. The loaders are equipped with advanced hydraulic systems that ensure smooth operation and precise control, facilitating high-performance outcomes, whether digging, lifting, or transporting materials.

In addition to their lifting capabilities, the Bobcat S175 and S185 excel in various functionalities through the use of changeable attachments. These machines can be customized with various tools, such as buckets, forks, and snowplows, thus broadening their application range significantly. This adaptability empowers operators to engage in multiple projects, enhancing productivity and efficiency.

Regular maintenance and servicing are vital to ensure these skid steer loaders maintain their peak performance and longevity. Adhering to a disciplined maintenance schedule not only minimizes the risk of breakdowns but also maximizes the return on investment for equipment owners. Therefore, understanding the specifics of the Bobcat S175 and S185, along with their operational requirements, is critical for anyone looking to invest in reliable and efficient machinery for their operational needs.

Essential Maintenance and Repair Procedures

Proper maintenance and timely repair procedures are paramount for the longevity and efficiency of Bobcat S175 and S185 Turbo skid steer loaders. Adhering to a structured maintenance schedule not only ensures optimal performance but also minimizes unexpected breakdowns. Operators should begin with routine maintenance checks that encompass inspecting fluid levels, such as engine oil, hydraulic fluid, and coolant. Regularly checking these levels can prevent potential issues and maintain operational efficiency.

Fluid changes are crucial, particularly for the hydraulic and engine oils. Over time, fluids can degrade, leading to increased wear on mechanical components. It is recommended that operators change engine oil every 250 hours of operation or as specified in the service repair manual. Additionally, hydraulic fluid should be replaced based on the manufacturer’s guidelines, often every 1,000 hours, to ensure peak performance and prevent hydraulic system failures.

Filter replacements are equally important in maintaining the S175 and S185 models. Air, oil, and hydraulic filters should be inspected and replaced according to the maintenance schedule provided in the service manual. Clogged filters can cause a host of operational issues, from reduced engine performance to hydraulic system inefficiencies. Operators must familiarize themselves with the locations of these filters to ensure they are accessible for routine checks and replacements.

Moreover, troubleshooting common issues is an essential skill for operators. Problems such as starting difficulties or unusual noises during operation can often be traced back to simple maintenance oversights. Utilizing the service repair manual is critical here; it serves as an invaluable resource, guiding operators through both minor repairs and complex troubleshooting tasks. By developing a thorough understanding of the manual, operators can effectively address maintenance needs and ensure their Bobcat skid steer loaders remain reliable and efficient.