Bobcat Soil Conditioner Service Repair Manual

$5.00

BEFORE YOU BUY FULL PDF MANUAL, PLEASE DOWNLOAD SAMPLE OF THIS PDF MANUAL AND PLEASE CHECK IT IS COMPATIBLE WITH YOUR MODEL

Description

Package Include

Bobcat Soil Conditioner Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-170

Publication Number

6901113

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 30 mb

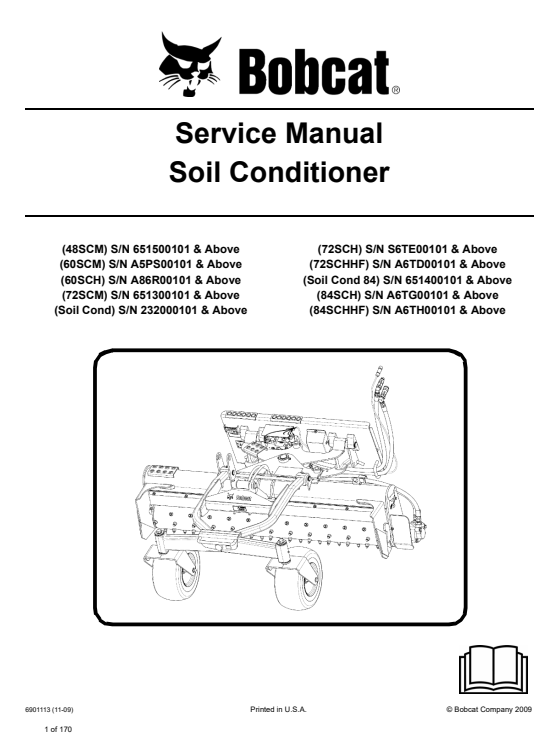

Compatible Machine Model : Bobcat Soil Conditioner

Compatible Serial Numbers :

(48SCM) S/N 651500101 & Above

(60SCM) S/N A5PS00101 & Above

(60SCH) S/N A86R00101 & Above

(72SCM) S/N 651300101 & Above

(Soil Cond) S/N 232000101 & Above

(72SCH) S/N S6TE00101 & Above

(72SCHHF) S/N A6TD00101 & Above

(Soil Cond 84) S/N 651400101 & Above

(84SCH) S/N A6TG00101 & Above

(84SCHHF) S/N A6TH00101 & Above

Understanding Your Bobcat Soil Conditioner

The Bobcat soil conditioner is a highly efficient and versatile piece of equipment designed to address a variety of land management and soil preparation tasks. It is particularly useful in landscaping, agricultural applications, and construction projects where proper soil conditioning is essential for optimal outcomes. One of the primary functions of the Bobcat soil conditioner is to finely grade and level the soil, which promotes effective seed growth and enhances drainage. With its adjustable wings and unique leveling capabilities, it can adapt to various terrains and soil types, making it a pivotal tool for professionals in the industry.

A comprehensive understanding of the components of the Bobcat soil conditioner is fundamental for its effective operation. The machine includes a robust frame, high-quality blades, and hydraulic systems that facilitate maneuverability and ease of use. The heavy-duty blades are engineered to penetrate tough soil conditions, while the hydraulic systems allow for precise control over depth and angle settings. Such specifications contribute significantly to the effectiveness of the equipment in preparing soil for planting or construction.

Regular maintenance of the Bobcat soil conditioner is essential to ensure longevity and performance. Users should frequently inspect key components, such as the blades and hydraulic fluid levels, to identify any potential issues before they escalate. Common problems can include blade wear and fluid leaks, both of which can hinder the machine’s performance. Additionally, understanding the specifications outlined in the service repair manual is critical for troubleshooting these issues effectively. By familiarizing themselves with these features and maintenance needs, operators can maximize their Bobcat soil conditioner’s efficiency, leading to enhanced productivity and reliability in their land management endeavors.

Step-by-Step Guide to Using the Service Repair Manual

Utilizing the Bobcat soil conditioner service repair manual effectively is crucial for efficiently diagnosing and addressing common mechanical issues. Begin by familiarizing yourself with the structure of the manual, which usually comprises sections dedicated to schematics, maintenance schedules, and routine check protocols. Understanding this layout will enhance your ability to navigate through various repair topics quickly.

Start with the schematics section, which provides detailed wiring diagrams and part layouts. These visual aids are essential for troubleshooting electrical or mechanical failures. When reading schematics, pay particular attention to symbols and color codes, which indicate specific functions and connections. This knowledge forms the basis for identifying faults in your equipment.

The maintenance schedule outlined in the manual details periodic tasks needed to keep your Bobcat soil conditioner operating efficiently. Regular maintenance extends equipment life, so refer to this schedule to ensure timely inspections and servicing. Each listed task, whether it’s replacing filters or conducting fluid checks, is vital for preventing larger issues down the line.

Moreover, the section on routine checks offers guidance on daily operational assessments. These checks typically entail inspecting hydraulic fluids, checking for leaks, and ensuring that all moving components are functioning smoothly. Adhering to these checks ensures that your soil conditioner remains in optimal condition.

When it comes to repair techniques, the manual emphasizes the importance of safety precautions. Always remember to wear appropriate personal protective equipment (PPE) and follow lockout/tagout procedures to prevent accidental equipment start-ups during repairs. Sourcing parts, whether from authorized dealers or aftermarket suppliers, is also covered extensively. With these resources at your disposal, you can confidently address any maintenance or repair challenge that comes your way.