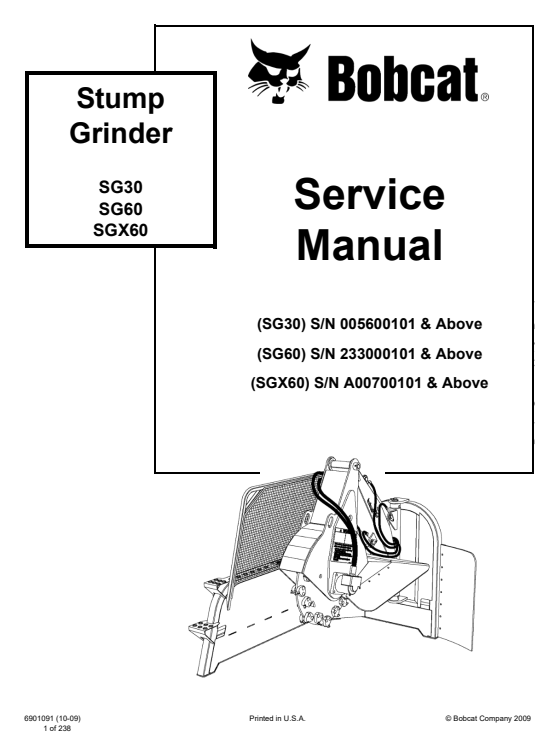

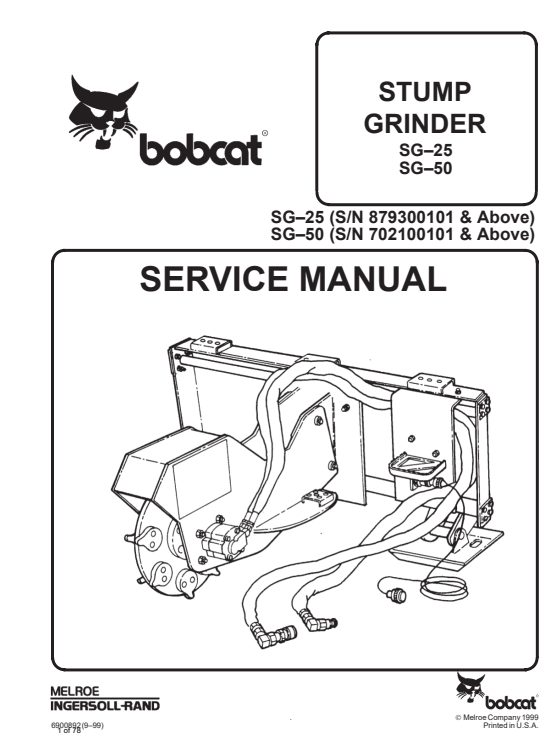

Bobcat Stump Grinder SG25, SG50 Service Repair Manual

$5.00

Description

Package Include

Bobcat Stump Grinder SG25, SG50 Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-78

Publication Number

6900892

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 16 mb

Compatible Machine Model :

Bobcat Stump Grinder SG25

Bobcat Stump Grinder SG50

Compatible Serial Numbers :

SG–25 (S/N 879300101 & Above)

SG–50 (S/N 702100101 & Above)

Introduction to Bobcat Stump Grinders SG25 and SG50

The Bobcat SG25 and SG50 stump grinders represent innovative machinery designed for efficient tree stump removal. These models are integral in landscaping, land clearing, and construction industries, showcasing a combination of power, precision, and ease of operation. By delving into the features and specifications of each model, users gain critical insights into their respective capabilities and performance metrics.

The SG25 model is engineered for medium-duty applications, suffice to handle stumps up to 12 inches in diameter, making it ideal for small to mid-sized projects. It possesses a robust 25-horsepower engine, ensuring ample torque and speed for optimal stump grinding efficiency. Furthermore, its compact design allows for maneuverability in tight spaces, enhancing its utility in residential landscaping and smaller commercial sites.

On the other hand, the SG50 stump grinder is suited for heavy-duty tasks, tackling larger stumps up to 20 inches in diameter. Equipped with a more powerful 50-horsepower engine, this model excels on more demanding job sites, delivering superior performance without compromise. Its advanced hydraulic system not only provides enhanced depth control but also results in smoother operation, which is crucial for achieving desirable outcomes in extensive land clearing projects.

Understanding the mechanics behind these stump grinders is paramount for effective operation and maintenance. Users who are familiar with how these machines function are better positioned to identify potential issues, maintain optimal performance, and prolong the lifespan of their equipment. Both hobbyists and professionals in landscaping and land management can benefit significantly from employing the Bobcat SG25 and SG50, as they accommodate a wide range of stump grinding needs while ensuring a high standard of work.

Essential Service and Repair Procedures for Stump Grinders

Maintaining the operational efficiency of Bobcat stump grinders, specifically the SG25 and SG50 models, requires adherence to essential service and repair procedures as outlined in the respective manuals. Routine maintenance plays a pivotal role in ensuring that these machines operate smoothly and effectively. Key tasks include regularly checking oil levels and replacing filters to prevent any mechanical failures due to insufficient lubrication or contamination.

Inspecting the cutting teeth for wear is another critical maintenance task. The cutting teeth are the primary contact elements responsible for grinding stumps and roots, and their condition directly influences the machine’s performance. When the teeth become dull or damaged, it not only hampers the efficiency of the grinder but can also lead to increased strain on the engine, resulting in more extensive repairs if not addressed timely.

Troubleshooting is a necessary skill for operators of the SG25 and SG50 models, as it allows for quick identification and resolution of common issues, such as engine performance problems and abnormal noise during operation. It is recommended to consult the service manual for detailed troubleshooting steps, which often include diagnostic checks and specific corrective actions.

Safety precautions are paramount when servicing stump grinders. Operators should always wear appropriate personal protective equipment, including gloves and safety glasses, when performing maintenance procedures. Additionally, it is essential to follow best practices, including ensuring the machine is powered down and disconnected from its power source before beginning any repair work. Preventative care, such as cleaning debris from the grinder and storing it in a dry environment, can extend the life of the equipment and enhance its performance.

Incorporating these procedures into a regular maintenance schedule will ensure the longevity and efficiency of Bobcat stump grinders, ultimately leading to improved performance and a reduction in repair costs.