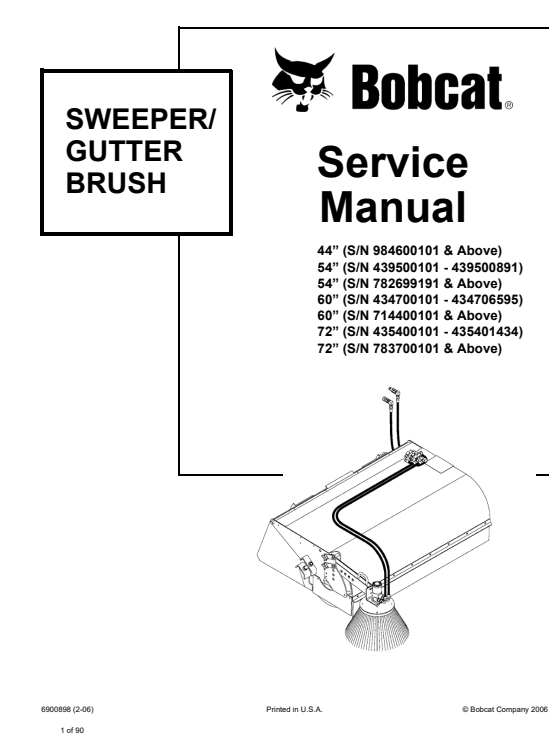

Bobcat Sweeper Gutter Bruch Service Repair Manual

$5.00

Compatible Machine Model : Bobcat Sweeper Gutter Bruch

Compatible Serial Numbers :

44” (S/N 984600101 & Above)

54” (S/N 439500101 – 439500891)

54” (S/N 782699191 & Above)

60” (S/N 434700101 – 434706595)

60” (S/N 714400101 & Above)

72” (S/N 435400101 – 435401434)

72” (S/N 783700101 & Above)

BEFORE YOU BUY FULL PDF MANUAL, PLEASE DOWNLOAD SAMPLE OF THIS PDF MANUAL AND PLEASE CHECK IT IS COMPATIBLE WITH YOUR MODEL

Description

Package Include

Bobcat Sweeper Gutter Bruch Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-90

Publication Number

6900898

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 19 mb

Compatible Machine Model : Bobcat Sweeper Gutter Bruch

Compatible Serial Numbers :

44” (S/N 984600101 & Above)

54” (S/N 439500101 – 439500891)

54” (S/N 782699191 & Above)

60” (S/N 434700101 – 434706595)

60” (S/N 714400101 & Above)

72” (S/N 435400101 – 435401434)

72” (S/N 783700101 & Above)

Understanding the Bobcat Sweeper Gutter Brush System

The Bobcat sweeper gutter brush system is an essential attachment designed to enhance the efficiency of your Bobcat loader while performing clean-up tasks. This system is specifically engineered to address the accumulation of debris, leaves, and other materials in gutters and along edges, ensuring a clean working environment. The gutter brush system comprises several components that work in unison to achieve optimal performance.

At the heart of the system is the motor, which powers the brushes and provides the necessary torque to handle various debris types. The brushes themselves are mounted on a durable frame that can be adjusted according to the type of surface being cleaned. These brushes come in different bristle types and stiffness levels, allowing users to select the most appropriate configuration for their specific cleaning needs. The mounting mechanism is crucial, as it enables easy attachment and detachment of the gutter brush, making it a versatile tool for various applications.

Maintaining the gutter brush system is vital for ensuring longevity and effective operation. Regular inspections should be carried out to identify potential issues such as wear and tear on the brushes or motor malfunctions. Common problems that may arise include clogged brushes, which can hinder performance, and uneven wear, which can reduce cleaning efficiency. Neglecting these maintenance requirements can lead to significant operational setbacks and increased repair costs over time. It is essential to follow the manufacturer’s guidelines to ensure the gutter brush operates smoothly. By understanding the components and functionality of the Bobcat sweeper gutter brush system, operators can appreciate the necessity of regular maintenance and the proper execution of repair procedures when issues arise, ultimately promoting better performance and a longer service life.

Step-by-Step Repair and Maintenance Procedures for Bobcat Gutter Brushes

Maintaining the Bobcat sweeper gutter brush system is essential to ensure its optimal performance and longevity. This section provides comprehensive, step-by-step procedures tailored for users to effectively manage repairs and maintenance tasks.

Begin with routine inspections at regular intervals, ideally at the start and end of each operational season. Inspect the gutter brush for any signs of wear, such as fraying bristles or cracks in the brush housing. Utilizing a checklist can help streamline this process. Checking the brushes’ connections and ensuring that they are secure is crucial to avoid operational issues during use.

Cleaning the gutter brush is another vital procedure. After each use, clear any debris, dirt, or materials that may hinder performance. Use a pressure washer for an effective deep clean, ensuring that all components are free from buildup. This not only enhances efficiency but also reduces the likelihood of premature wear.

When it comes to replacing worn or damaged parts, it is essential to follow a systematic approach. First, remove the gutter brush assembly from the sweeper by unscrewing the retaining bolts. Replace any compromised brushes and ensure that new components meet the original specifications. Reassemble the unit, making sure that all fittings are secure and correctly aligned.

Diagnosing common problems, such as poor performance or unusual noises, can save time and resources. If the gutter brush appears to struggle, check for motor functionality and inspect for blockages. Noises can often indicate deterioration in the bearings, necessitating a prompt inspection and possible replacement. It is advisable to have all necessary tools on hand, including wrenches, screwdrivers, and replacement parts.

Safety is paramount during any maintenance activity. Always wear appropriate personal protective equipment, and ensure that the sweeper is turned off and disconnected from its power source before starting any repairs. By following these guidelines, Bobcat users can ensure that their gutter brush systems remain efficient and reliable over time.