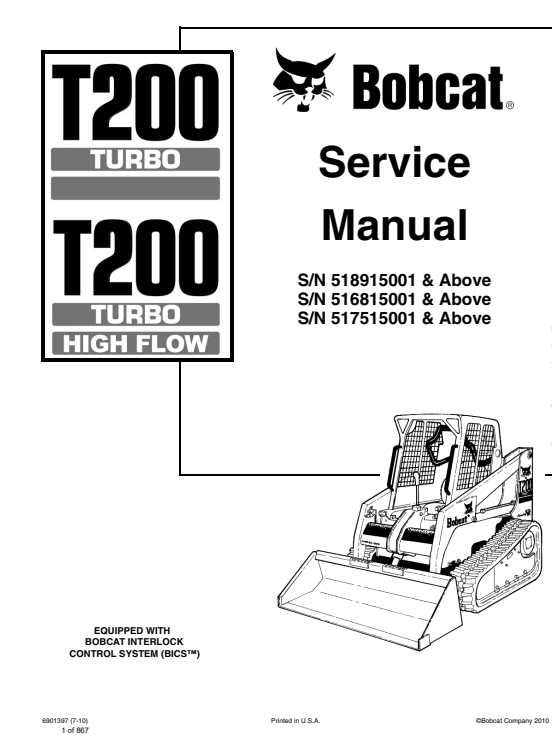

Bobcat T200 Turbo SkidSteer Loader Service Repair Manual

$5.00

Description

Package Include

Bobcat T200 Turbo SkidSteer Loader Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-867

Publication Number

6901397

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 317 mb

Compatible Machine Model : Bobcat T200 Turbo SkidSteer Loader

Compatible Serial Numbers :

S/N 518915001 & Above

S/N 516815001 & Above

S/N 517515001 & Above

Understanding the Bobcat T200 Turbo: Specifications and Features

The Bobcat T200 Turbo Skid Steer Loader is a powerful and versatile machine, specifically engineered to excel in various construction, landscaping, and agricultural tasks. This model boasts a compact design, with overall dimensions that facilitate maneuverability in tight spaces while ensuring stability on uneven terrain. Measuring approximately 60 inches wide and standing at about 73 inches tall, the T200 Turbo is adept at navigating through job sites with limited access.

At the heart of this skid steer loader is its robust turbocharged engine, delivering an impressive output of around 66 horsepower. This feature not only enhances the machine’s performance but also optimizes fuel efficiency, allowing operators to complete tasks without frequent refueling. The operational weight of the T200 Turbo is approximately 7,000 pounds, providing the necessary heft to handle substantial lifting and digging loads, with a lift capacity reaching up to 2,000 pounds. This remarkable capacity allows the T200 Turbo to efficiently manage heavy materials, increasing productivity across various applications.

The hydraulic system of the Bobcat T200 Turbo further amplifies its capabilities. With a powerful hydraulic pump, the loader offers superior lift and tilt forces, making it an exceptional tool for loading, grading, and excavation tasks. Its hydraulic fluid flow is essential for operating a wide range of attachments, from buckets to augers, which enhances the machine’s versatility for multiple job site needs.

Moreover, consulting the service and repair manual is essential for maintaining optimal performance and extending the longevity of the Bobcat T200 Turbo. This comprehensive guide provides crucial information on maintenance schedules, troubleshooting, and repairs, ensuring that the skid steer loader operates at peak efficiency for years to come.

Essential Maintenance and Repair Procedures from the Service Manual

The Bobcat T200 Turbo Skid Steer Loader is a vital piece of machinery in various industries, necessitating proper maintenance and repair procedures to ensure its optimal performance. According to the service and repair manual, thorough maintenance is essential to prolong the lifespan of this skid steer loader and maintain safety on job sites. Scheduled maintenance tasks, which include oil changes and filter replacements, should be performed at regular intervals as specified in the manual. These procedures are crucial for preventing operational failures that could lead to costly downtime.

One of the first maintenance tasks is the regular oil change. The manual recommends using the specified type of oil to ensure that the engine operates efficiently. Neglecting oil changes can lead to engine wear and eventual failure. Additionally, filter replacements, particularly the oil and hydraulic filters, are critical for keeping contaminants out of the system, promoting smoother operation and prolonging the life of the loader.

Inspection of hydraulic systems is another vital aspect of the T200 Turbo’s maintenance. Signs of hydraulic fluid leaks or irregular noises should be addressed immediately, as outlined in the service manual. Regularly checking hoses, fittings, and the hydraulic fluid level helps ensure that the machine operates at optimal efficiency, reducing the risk of severe damage.

For effective troubleshooting, the manual provides guidance on common issues like starting difficulties and mechanical performance problems. It highlights specific diagnostics and the tools required for each task. Safety protocols must be adhered to throughout all maintenance procedures; this includes proper use of personal protective equipment and ensuring the machine is on stable ground before commencing work. Step-by-step instructions facilitate easy navigation through repairs, making it essential to refer to the service manual for effective maintenance and repair practices.