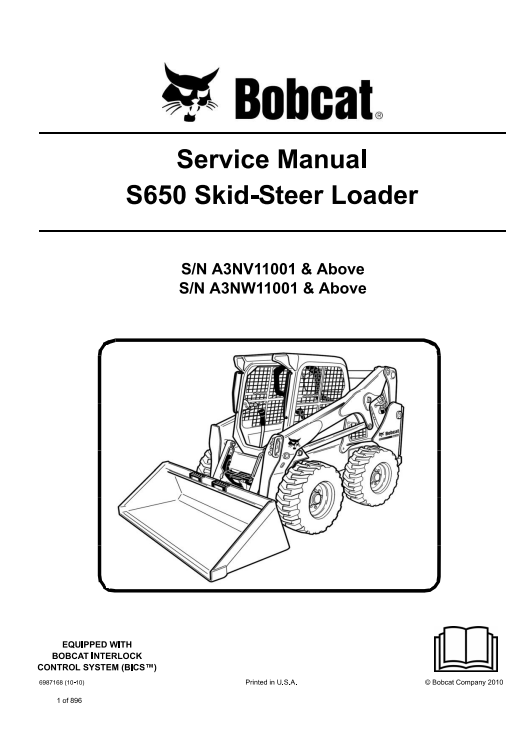

Bobcat S650 SkidSteer Loader Service Repair Manual

$5.00

Description

Package Include

Bobcat S650 SkidSteer Loader Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-896

Publication Number :

6987168

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 48 mb

Compatible Machine Model : Bobcat S650 SkidSteer Loader

Compatible Serial Numbers :

S/N A3NV11001 & Above

S/N A3NW11001 & Above

Overview of the Bobcat S650 Skid Steer Loader

The Bobcat S650 skid steer loader stands out in the competitive landscape of compact construction equipment due to its exceptional specifications, advanced features, and versatile capabilities. Powered by a robust diesel engine, the S650 produces ample torque and horsepower, providing optimal performance for various tasks. The engine specifications include a powerful 74 horsepower, allowing the loader to efficiently handle demanding jobs with ease.

One of the standout features of the Bobcat S650 is its hydraulic system, which offers superior lifting capabilities. The loader boasts a vertical lift design, enabling it to lift heavy loads with a maximum operating capacity of approximately 2,690 pounds. This significantly enhances productivity, allowing for the quick and efficient loading and unloading of materials, making it a suitable choice for construction sites and landscaping projects.

In terms of dimensions, the S650 is compact yet powerful. With a width of 65 inches and an operating weight of about 7,246 pounds, it is designed to maneuver easily in tight spaces while still providing the stability required for heavy lifting. This makes it an invaluable asset in urban construction settings, where space can often be constrained.

The Bobcat S650 also features a range of attachments and technologies that enhance its performance. Its enhanced hydraulic system allows for quick and effortless switching between different attachments, such as buckets, forks, and grapples. Additionally, the machine is equipped with Bobcat’s advanced control systems, which improve operator comfort and efficiency. These features contribute to the loader’s widespread application across various industries, including construction, agriculture, and landscaping, solidifying its reputation as a versatile and reliable skid steer loader favored by contractors and construction professionals alike.

Importance of the Service Repair Manual

The Bobcat S650 skid steer loader is a versatile and powerful machine essential for various tasks in construction, landscaping, and agricultural settings. However, like any complex equipment, it requires regular maintenance and occasional repairs to ensure optimal performance. This is where the service repair manual becomes crucial. It serves as an authoritative resource that provides detailed information on the necessary maintenance protocols and repair methodologies.

The service repair manual is designed to equip owners and operators of the Bobcat S650 with step-by-step guidance on troubleshooting and diagnostics. This includes clear instructions for routine servicing tasks such as oil changes, filter replacements, and lubrication practices. Furthermore, these manuals delve into more complex tasks, offering insights into the electrical system, engine maintenance, and hydraulic repairs. By consulting the manual, users can efficiently identify issues before they escalate, thereby reducing downtime and repair costs.

Adhering to the maintenance schedules outlined in the service manual significantly contributes to the longevity of the Bobcat S650. Regular upkeep not only enhances the operational efficiency of the machine but also plays a vital role in ensuring safety during operation. A well-maintained skid steer loader reduces the risk of accidents and mechanical failures, providing operators with peace of mind while working in demanding environments.

Moreover, utilizing the service repair manual fosters a deeper understanding of the equipment, allowing users to identify potential problems early in their development. This proactive approach to maintenance can save owners both time and money by minimizing emergency repairs and unexpected equipment replacements.