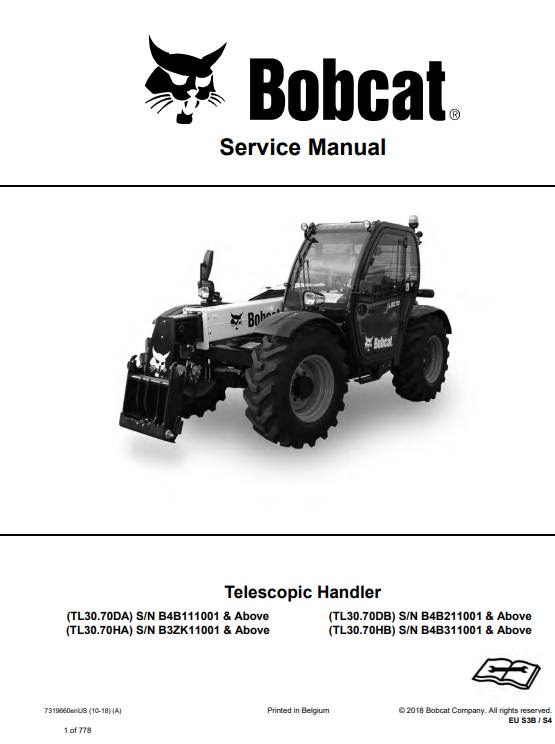

Bobcat TL34.65C, TL34.65XC, TL35.70, TL38.70, TL38.70X Telescopic Handler Service Repair Manual

$5.00

Compatible Machine Model :

Bobcat TL34.65C Telescopic Handler

Bobcat TL34.65XC Telescopic Handler

Bobcat TL35.70 Telescopic Handler

Bobcat TL35.70X Telescopic Handler

Bobcat TL38.70 Telescopic Handler

Bobcat TL38.70X Telescopic Handler

Compatible Serial Numbers :

(TL34.65C) B41N11001 – 16000 & B41N16001 & Above (VIN BCFB41NNXJ0D16001 & Above)

(TL34.65XC) B41P11001 – 16000 & B41P16001 & Above (VIN BCFB41PNXJ0D16001 & Above)

(TL35.70) B3ZS11001 – 16000 & B3ZS16001 & Above (VIN BCFB3ZSKXJ0D16001 & Above)

(TL35.70X) B3ZT11001 – 16000 & B3ZT16001 & Above (VIN BCFB3ZTKXJ0D16001 & Above)

(TL38.70) B3ZU11001 – 16000 & B3ZU16001 & Above (VIN BCFB3ZUNXJ0D16001 & Above)

(TL38.70X) B3ZV11001 – 16000 & B3ZV16001 & Above (VIN BCFB3ZVNXJ0D16001 & Above)

Description

Package Include

Bobcat TL34.65C, TL34.65XC, TL35.70, TL38.70, TL38.70X Telescopic Handler Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-913

Publication Number :

7283184

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 144 mb

Compatible Machine Model :

Bobcat TL34.65C Telescopic Handler

Bobcat TL34.65XC Telescopic Handler

Bobcat TL35.70 Telescopic Handler

Bobcat TL35.70X Telescopic Handler

Bobcat TL38.70 Telescopic Handler

Bobcat TL38.70X Telescopic Handler

Compatible Serial Numbers :

(TL34.65C) B41N11001 – 16000 & B41N16001 & Above (VIN BCFB41NNXJ0D16001 & Above)

(TL34.65XC) B41P11001 – 16000 & B41P16001 & Above (VIN BCFB41PNXJ0D16001 & Above)

(TL35.70) B3ZS11001 – 16000 & B3ZS16001 & Above (VIN BCFB3ZSKXJ0D16001 & Above)

(TL35.70X) B3ZT11001 – 16000 & B3ZT16001 & Above (VIN BCFB3ZTKXJ0D16001 & Above)

(TL38.70) B3ZU11001 – 16000 & B3ZU16001 & Above (VIN BCFB3ZUNXJ0D16001 & Above)

(TL38.70X) B3ZV11001 – 16000 & B3ZV16001 & Above (VIN BCFB3ZVNXJ0D16001 & Above)

Overview of Bobcat Telescopic Handlers

Bobcat telescopic handlers are renowned for their versatility and efficiency in various operational contexts. Models such as the TL34.65C, TL34.65XC, TL35.70, TL38.70, and TL38.70X are specifically engineered to meet the demands of sectors such as construction and agriculture. These machines feature advanced technical specifications that cater to a wide range of tasks. For instance, the TL34.65C and TL34.65XC models offer lifting capacities that facilitate the handling of significant loads, making them indispensable on job sites where durability and power are paramount.

One of the key features of these telescopic handlers is their maneuverability. Designed for both indoor and outdoor use, they are capable of navigating tight spaces with ease; this is particularly advantageous in construction environments where space is limited. The compact designs of these handlers enable operators to perform tasks with precision, contributing to increased productivity and efficiency.

In addition to their robust lifting capabilities, Bobcat telescopic handlers are equipped with various attachments, allowing them to perform multiple functions. Whether it involves lifting heavy materials or transporting goods across challenging terrains, these machines adapt well to different applications. Their versatility extends further with advanced hydraulic systems that deliver smooth operation and precise control, enhancing user experience and safety.

Moreover, the reliability and performance of these models have made them popular choices among contractors and agricultural professionals alike. Their robust construction ensures longevity, reducing downtime and maintenance costs over time. Overall, the TL34.65C, TL34.65XC, TL35.70, TL38.70, and TL38.70X models represent a significant investment for industries seeking efficient and effective solutions in material handling.

Service Repair Guidelines for the Bobcat TL34.65 and TL38 Models

Service and repair procedures for the Bobcat TL34.65 and TL38 models are essential for ensuring optimal performance and longevity. Following a structured maintenance schedule can significantly reduce the likelihood of equipment malfunctions. Operators are encouraged to consult the manufacturer’s service manual for specific intervals; typically, these may include daily, weekly, and monthly checks. Routine inspections should cover fluid levels, air filters, and hydraulic systems to identify potential issues before they escalate.

Troubleshooting common issues requires knowledge of the machine’s operational characteristics and functionality. For instance, if the telescopic handler experiences a decrease in lifting capacity, this could be indicative of hydraulic concerns or structural strain. Addressing these problems promptly through systematic diagnosis will often lead to more straightforward repairs and better machine reliability.

When it comes to performing repairs, utilizing OEM (Original Equipment Manufacturer) parts is imperative. OEM parts guarantee the same level of quality and performance as originally equipped by the manufacturer, ensuring compatibility and reliability. Additionally, employing the recommended tools can facilitate efficient repairs. These tools often include specialized hydraulic jacks, wrenches, and electronic diagnostic devices that aid in identifying faults.

Implementing safety practices is crucial during any service operation. Operators should always wear appropriate personal protective equipment when conducting maintenance or repairs to minimize injury risks. It is also advisable to ensure the work area is clean and well-lit to avoid accidents associated with tripping or reduced visibility.

In addition to the outlined procedures, adopting good maintenance habits can help optimize the performance of the Bobcat TL34.65 and TL38 models. Regular lubrications, timely fluid changes, and attentive cleaning can extend the lifespan of the machines, allowing them to operate efficiently under various conditions.