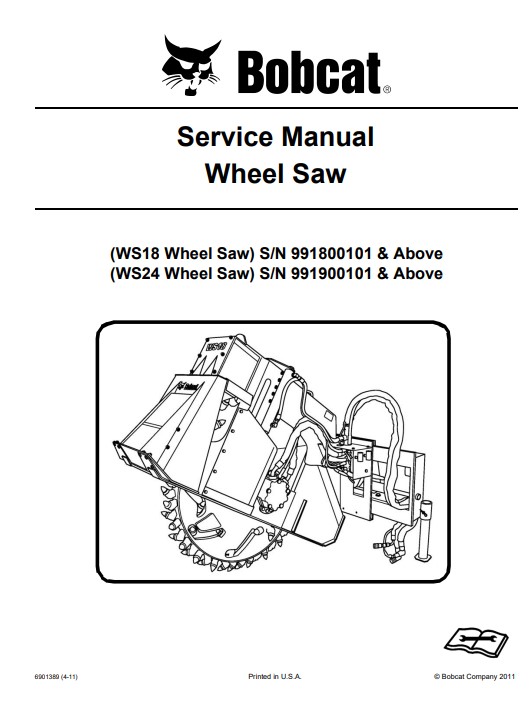

Bobcat WS18 , WS24 Wheel Saw Service Repair Manual

$25.00

BEFORE YOU BUY FULL PDF MANUAL, PLEASE DOWNLOAD SAMPLE OF THIS PDF MANUAL AND PLEASE CHECK IT IS COMPATIBLE WITH YOUR MODEL

Description

Package Include

Bobcat WS18 , WS24 Wheel Saw Service Repair Manual

Language

English

Format

PDF

Total Number of pages

1-171

Publication Number

6901389 (4-11)

Compatible

All windows and mac systems

Additional Requirement

User needs to Install PDF Reader Software

Shipping Policy

Download link by high speed web server Total Download size 9 mb

Overview

With This Original factory Service Repair Manual The Technician can solve any problems encountered in the operation of your Bobcat Wheel Saw Models of :

WS18 [S.N 991800101 & Above]

WS24 [S.N 991900101 & Above]

CONTENTS OF THIS SERVICE MANUAL

SAFETY AND MAINTENANCE

HYDRAULIC SYSTEM

MAIN FRAME

SPECIFICATIONS

ALPHABETICAL INDEX

TO CONFIRM IS THIS SERVICE MANUAL COMPATIBLE WITH YOUR MACHINE MODEL PLEASE DOWNLOAD SAMPLE

[the_ad id=”23726″]

Understanding Bobcat WS18 and WS24 Wheel Saws

The Bobcat WS18 and WS24 wheel saws are powerful and efficient attachments designed for a variety of cutting tasks in different applications. Both models are specifically engineered to provide enhanced performance and reliability, whether you are working on road construction, utility installation, or various landscaping projects. Understanding the specifications and features of these wheel saws can help operators choose the appropriate model for their task.

The WS18, with its compact design, is particularly suitable for tighter spaces and has a maximum cutting depth of 18 inches. It is ideal for smaller-scale jobs where precision is crucial. On the other hand, the WS24 boasts a more robust construction, allowing for a maximum cutting depth of 24 inches. This makes it better suited for larger projects where deep cutting is required. Both models are designed to optimize power and can be utilized effectively in diverse conditions.

Key differences between the WS18 and WS24 are not only limited to cutting depths but also extend to their operational capabilities and performance in different environments. Operators should evaluate the specific requirements of their projects to select the appropriate saw that maximizes effectiveness and productivity.

Additionally, having access to a service repair manual is crucial for the maintenance and longevity of these machines. Such manuals provide essential guidance on routine maintenance, troubleshooting, and repairs, empowering owners and operators to diagnose issues and make informed decisions regarding their equipment. Conducting proper maintenance not only extends the lifespan of the Bobcat wheel saws but also ensures optimal performance, allowing operators to complete their tasks efficiently.

Familiarizing oneself with the technical aspects and operational guidelines of the Bobcat WS18 and WS24 wheel saws can significantly enhance the user experience, making it easier for both novices and experts to harness their capabilities effectively.

Service and Repair Manual: Essential Guidelines and Best Practices

The Bobcat WS18 and WS24 wheel saws are robust tools designed for various cutting tasks in construction and landscaping. To ensure their longevity and optimal performance, adhering to the essential guidelines and best practices outlined in the official service repair manuals is pivotal. Regular maintenance tasks must be meticulously scheduled to prevent potential failures and extend the operational lifespan of these machines.

One of the primary maintenance tasks involves the periodic checking and replacement of the blades. Ensuring that blades are sharp and free from damage not only affects cut quality but also impacts the efficiency of the saw. Operators should routinely inspect the condition of blades, replacing them when signs of wear or dullness are apparent. Additionally, lubricating moving parts is crucial in maintaining proper functionality; regular lubrication minimizes friction and wear, thus enhancing the overall performance and reliability of the wheel saws.

Inspection of hydraulic systems is another critical aspect of service. Operators must look for leaks, damaged hoses, and ensure the hydraulic fluid levels are within the recommended range. Addressing these issues promptly can prevent serious mechanical problems that might arise from neglecting the hydraulic system. Common mechanical issues, such as motor malfunctions and operational anomalies, can often be resolved through the comprehensive troubleshooting guidance provided in the service manuals.

Safety precautions are paramount when conducting service work. Operators should always disconnect power sources, wear appropriate personal protective equipment (PPE), and follow the guidelines outlined in the service manual to mitigate risks. By leveraging the available troubleshooting tips and accessing additional resources like warranty information and support contacts, users can actively contribute to maintaining their Bobcat WS18 and WS24 wheel saws. Following these best practices ensures that the machines operate efficiently, ultimately enhancing productivity in the field.